Business & Products

PT. TOTAL BIOFUEL INDONESIA (TBI) is a private owned company, focusing in the biomass energy sector, located in Jakarta, Indonesia.

Founded in October 2021 as a local subsidiary of TTS Planning Co., Ltd. (located in Fukuoka, western Japan) , PT. TOTAL BIOFUEL INDONESIA has built a stockpile for Palm Kernel Shells (PKS) in Tanah Grogot, Kalimantan Timur (East Borneo).

One of our current focuses is to supply PKS domestically, to biomass energy sourced power plants, textile factories and cement plants in Indonesia, as an alternative fuel for coal.

We also aim to provide to Japan in near future, mainly to our parent company’s 50MW biomass power plant, which started operating in August 2023.

Business Flow

Our business scope extends from Collection, Selection, Processing, Storage to Export

GGL Certification

- TBI plans to obtain GGL certification by the end of 2023.

- TBI actively encourages oil palm plantations in Indonesia to obtain GGL certification.

- Once obtaining certification to both TBI and oil palm plantations in Indonesia, TBI will start its supply to Japan, where the parent company TTS Planning Co., Ltd. invests in the 50MW biomass power plant “Kanda”, with the possibility of 100,000MT (metric tons) of PKS per year.

- Taking overseas expansions into consideration, TBI intends build additional stockpiles with roof, concrete floor, screening machines, etc. to maintain even higher quality for the future customers.

What’s GGL?

GGL is an international certification for sustainable biomass established by Green Gold Label Foundation in 2002. It covers the complete supply chain from production, processing, transport to final use for bioenergy, requiring high standers for tracked and traced sustainable biomass products. https://greengoldlabel.com/

It will be one of the third-party certification that METI (Ministry of Economy, Trade and Industry in Japan) requires in the guideline for the FIT scheme in Japan. (Expected after April 2024)

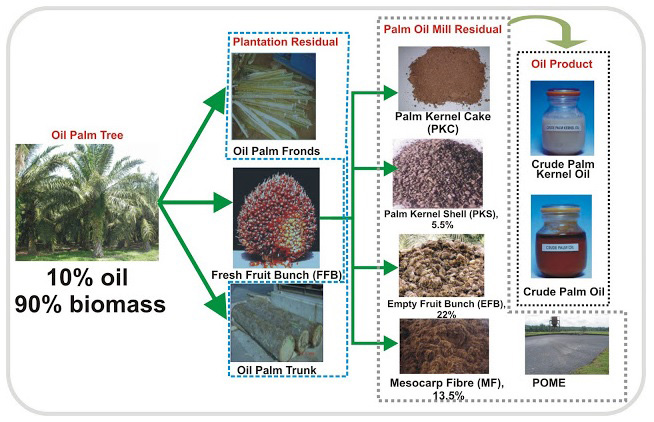

What is PKS?

- Palm Kernel Shells (PKS) is a by-product generated in the process of producing palm oil. It is the shell fractions left after the crushing of the palm oil nut in the palm oil mill.

- Large quantities of the residue are being produced in Indonesia, Malaysia and Thailand because of the increased market of palm oil around the world.

- PKS can be used as a biofuel, an alternative resource to replace fossil fuel. It is mainly utilized for supplying the heat needs of boilers in palm oil mills, concrete factories, or biomass-based power plants.

Source: https://www.biofuels.co.jp/index.html

Why PKS?

High Calorific Value

- 3500~4800kcal/kg, which is around 2 times more calorie than wood as it obtains palm oil

- cf. Wood chip 2100kcal / Wood pellet 3800kcal

- Fast combustion process due to the low humidity level

Easy Handling

- Low water content enables bulk transportation

- Resistant to soaking, thus able to stock outside

- Low ash and low sulfur content

Carbon Neutral

- Absorbs CO2 when they grow, offsets the CO2 emitted during combustion, resulting in a net zero impact on atmosphere

- Omits less CO2 with high evaporation rate, considered as an ecofriendly alternative for coals or other natural recourses

- FIT approved (Japan’s Feed-In Tariff Scheme by the Ministry of Economy, Trade, and Industry (METI) )

High Demands

- PKS market is expected to witness significant growth in the coming years, as the demand for renewable energy source rises

- In Japan, the import of PKS rose from 2,450,000MT (metric tons) in 2019 to 5,100,000 MT in 2022, nearly doubled within 3 years.

- Installed capacity of Biomass power in Japan was 4.5GW in 2019 then grew to 6.9GW in 2022, expects to reach 8.0GW by 2023.